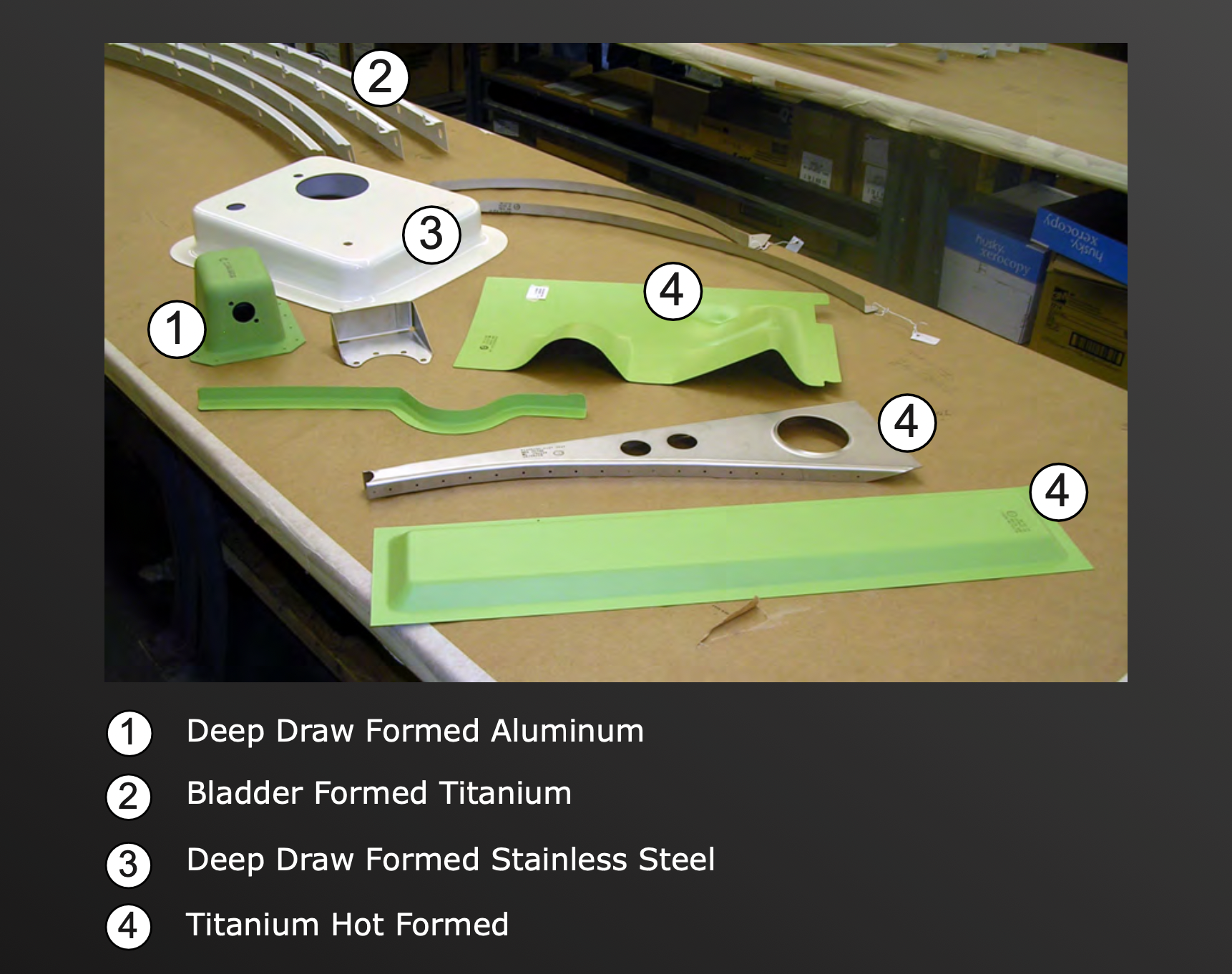

Metal Forming

We continually develop our metal forming capabilities in response to customer interest. If you think what you need can’t be made—ask us. Some of the equipment we employ for metal forming was designed and built by D-J Engineering to further expand our ability to make difficult parts.

Form dies are made by our own tooling department. You get the advantage of one call, one PO, one supplier, one integrated product. In addition to conventional forming methods, our patented CNC Stylus Forming Process enables us to form and trim to expand further our CNC mills in a single setup. We accomplish both metal forming and heat treatment to the highest standards.

The best equipment deserves the best and most experienced staff. Many projects involve a project engineer deployed on the shop floor to continually follow the progress. Our hand-forming staff ensures that the completed product is formed to your specifications.